Staff shortages in commercial laundries worldwide are driving automation efforts, particularly in the labor-intensive finishing side of linen, uniform and facility services plants. Below we highlight progress that a German company is making in this area.

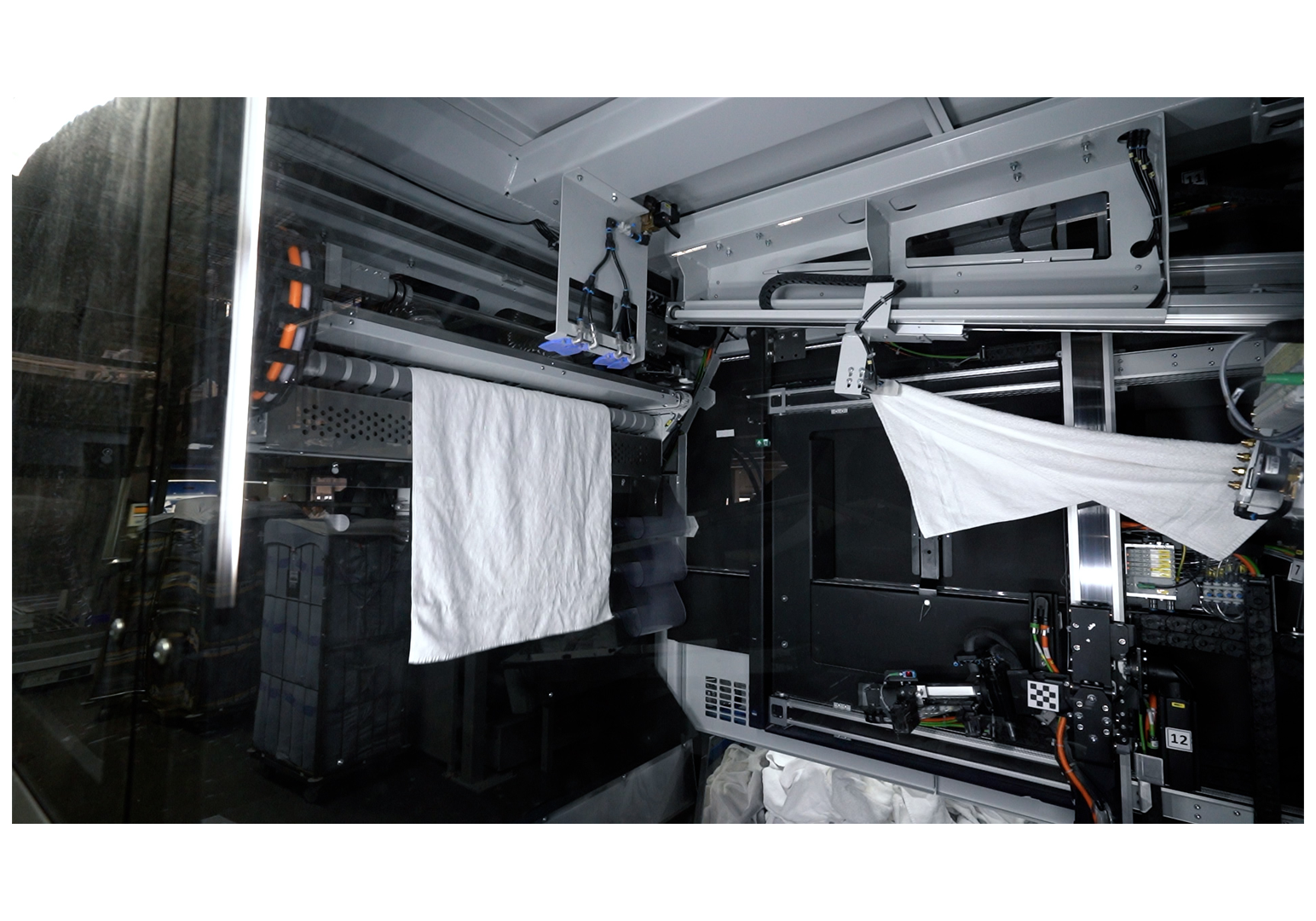

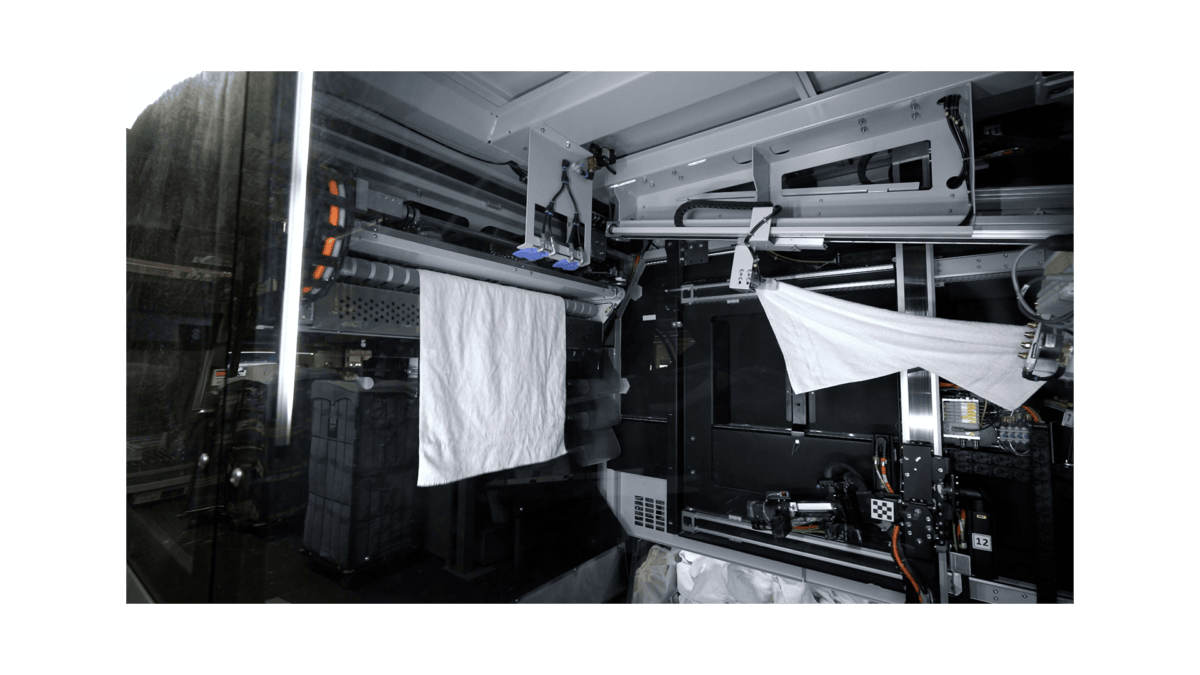

Textile Services Weekly recently interviewed Mike Hoppe, plant manager for the Kruppert Wäsche-Dienst facility in Hunfeld, Germany. He answered our questions about the company’s automated finishing system from Kannegessier, noting that it’s used to process towels and other flatwork items at this 41,980-square-foot (3,900-square-meter) laundry in central Germany.

As for productivity, human operators can move more goods per hour with manual feeding, he said. But Hoppe added that by running the automated equipment longer, the laundry can make up the difference. What’s more, automated feeders don’t need breaks or time off. Installed in 2020, the robotic finishing equipment is contributing to an overall throughput of nearly 8,000 lbs. (3,628 kg.) per hour. The plant’s weekly output varies, based on demand from its hospitality and food-and-beverage (F&B) customers.

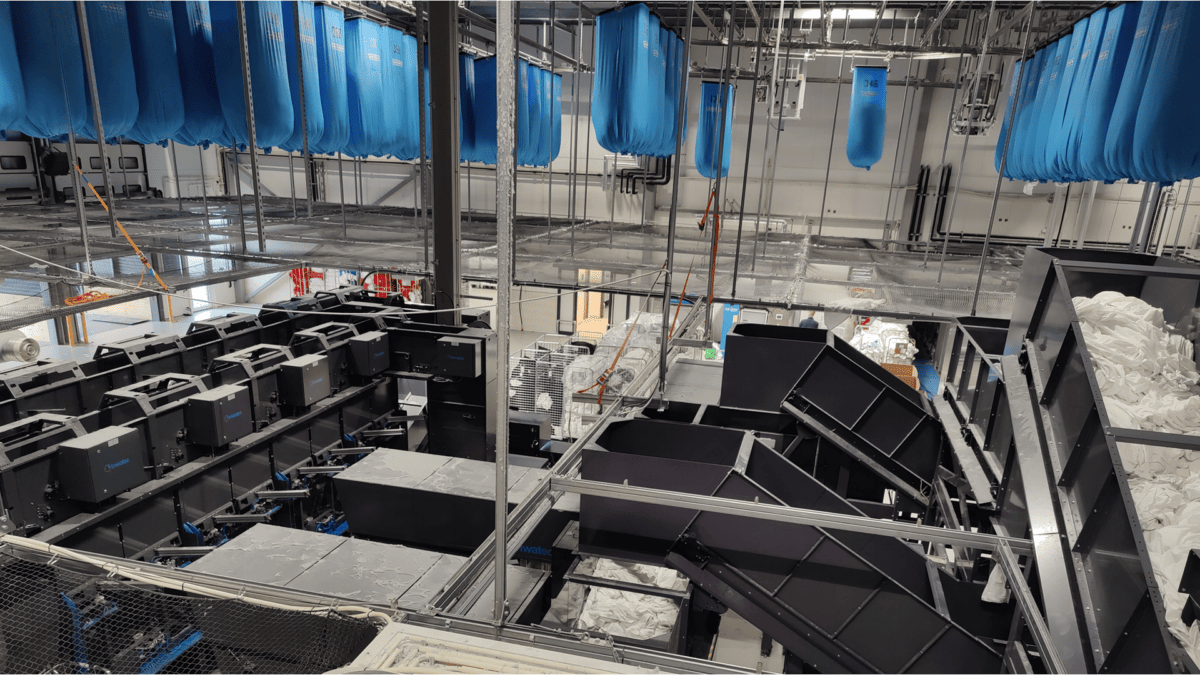

The laundry’s RFT Dry Work Line combines 3-D camera technology, intelligent image evaluation and ServoTronic robotics to deliver speed, precision and control. The RFT handles an average of 600-800 items per hour, with 2-3 batch changes per hour. As demand for automated solutions expands, the RFT Dry Work Line is positioned to fuel productivity for laundries worldwide. More than 65 of these units are already in use in Europe, and the technology has proven effective and reliable, Hoppe said. Kannegiesser is now planning to roll out the RFT Dry Work Line in North and South America as well.

As for upkeep, Hoppe says his team has virtually no issues with the automated-feeding system. “If the cleaning and maintenance schedules are followed, there are usually no difficult problems,” he said. In most cases, outside help isn’t needed. “We can resolve most of the issues ourselves.”

When asked if other commercial laundries similar to his should pursue automation of their finishing and wash processes, Hoppe said his answer is “a very clear YES.” The RFT Dry Work Line’s ability to handle a high volume of items with precision and reliability makes it a valuable addition to any laundry facility.

Kannegiesser ETECH plans to exhibit the RFT Dry Work Line at the 2025 CLEAN Show, Aug. 23-26 in Orlando. Attendees can see live demonstrations of the system on the show floor.

Sign Up For Our Newsletter

Receive the latest updates on the linen, uniform and facility services industry from TRSA delivered straight to your inbox.